Nick-Break Test

The purpose of the nick-break test is to permit evaluation of any weld defects across the fractured surfaces of a butt weld.

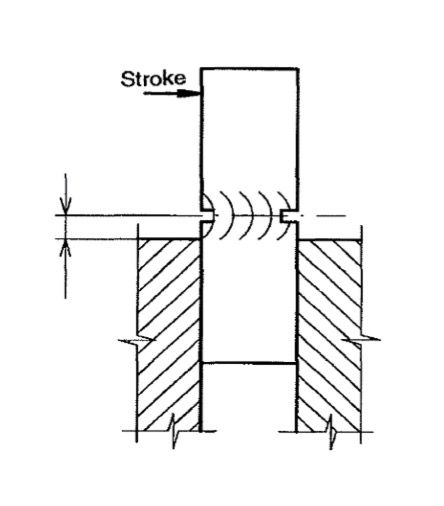

Two nicks (saw cuts approximately 2 mm deep) are applied to the specimen of similar shape to a bend test specimen, one on either side of the weld from the cap to the root. The weld reinforcement is left intact.

The test specimens are broken by bending or striking with a hammer. This causes the weld to fracture along the weakest zone close to the centre line of the weld. The fractured faces are then assessed visually. The test report would give a full description of the fractured faces including the presence of defects stating type and region.